Hulshof Royal Dutch Tanneries

Since it's founding in 1876, The Hulshof Royal Dutch Tanneries has grown into a modern ISO 9000:2000 certified “world center of excellence”. The company is still located in Lichtenvoorde, a small town in the eastern part of the Netherlands. Hulshof employs 200 highly involved employees and today it processes approximately 300.000 fresh North-West European Bull hides annually.

Since it's founding in 1876, The Hulshof Royal Dutch Tanneries has grown into a modern ISO 9000:2000 certified “world center of excellence”. The company is still located in Lichtenvoorde, a small town in the eastern part of the Netherlands. Hulshof employs 200 highly involved employees and today it processes approximately 300.000 fresh North-West European Bull hides annually.

These hides are being processed in the most environmentally friendly and efficient way the industry offers. We apply the same method for by-products of hide processing. These products are distributed to the food-industry and are represented by our subsidiary Hulshof Protein Technologies. The grain side of the hide is processed and sold as semi-manufactured food additive. The major part of the hide is processed into the finest quality upholstery leather in our leather finishing facility all on the same site.

In Europe Hulshof possesses a leading position in commercial and residential furniture, marine and the aviation markets. In order to keep this position, we work close with designers, customers, suppliers and partners to improve our current offerings but also focus on the future developments. Only by interacting with these parties, we can anticipate and change our technology and competency to the constantly changing environmental circumstances.

History

Royal Dutch Tanneries located in Lichtenvoorde, the Netherlands, was established in 1876 and flows from Hulshof Vleeswaren BV (1847), when the eldest son had the responsibility of tanning the hides of the slaughtered cattle. In 1895 the company moved to the grazing lands outside of Lichtenvoorde where it is still located. The town of Lichtenvoorde continued to grow so that it now surrounds our tannery. When the first steam engine was installed in the factory in 1898 it also provided electricity for half of Lichtenvoorde.

The outbreak of WWI (1914-1918) severely restricted the supply of tanning extracts from the foreign countries. In 1916 the decision was made to produce tanning extracts ourselves to be independent from war perils. In 1918 the new factory was reduced to ashes by a major fire.

It was in 1972 that the transition took place from the stiff shoeleather, which was produced in half hides, to the supple upholstery leather, which is produced in whole hides. In 1976 the Hulshof Dutch Tanneries received the designation 'Royal'. The criteria for this honor are: more than 100 years in business, an impeccable record of service and more that 100 employees.

In 1992 the decision was made to open a division in the United States. Hulshof Leather USA was formed and located in Hickory North Carolina in the heart of the United States furniture industry. Within 3 years the new company had outgrown its original facility and a new and larger office/warehouse was built. In 2005, new plans were drawn to increase this building by 50% to accommodate an ever growing business. Hulshof’s is proud to supply many of the finest and best known furniture manufacturers in the United States today.

From the Eighties the company grew with an average of more than 10% annually. The strength of Hulshof is the combination of a very stable production process (ISO 9001-2000) and a team of product-developers who work together with our customers to develop fresh new ideas for the furniture industry. Combining this with our worldwide team of sales and marketing professionals explains our continuing growth and success.

In 2001 we achieved our production goal of 1250,000 m2 and expansion plans are now in the works to increase to 2,000,000 m2 in the near future. To realize this expansion, with a minimum impact on the water quality in our community, Hulshof has completed construction of a state of the art high tech anaerobic biological purification plant built on the outskirts of town.

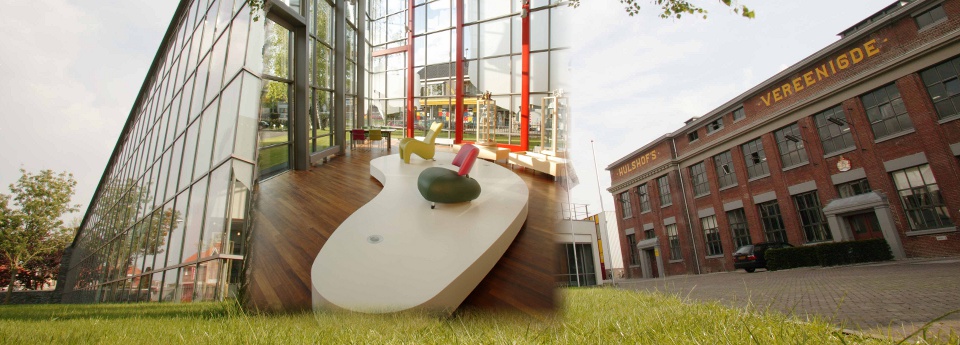

Recently, growth and expansion made it necessary for Hulshof to build a new office complex. Aware of the traditional image from this ever so innovative company, our architect succeeded in altering perception by creating a hypermodern building, which expresses the forward thinking of our company while at the same time reflecting the open culture in the company that is so important for its success.